Solutions for the challenges ofyarn processing

Textile mills present very demanding environmental conditions, often involving high temperatures and large variations in relative humidity. Our application engineers , technicians, and fabrication specialists deliver customized expert advice, quality customer service, and ongoing support .

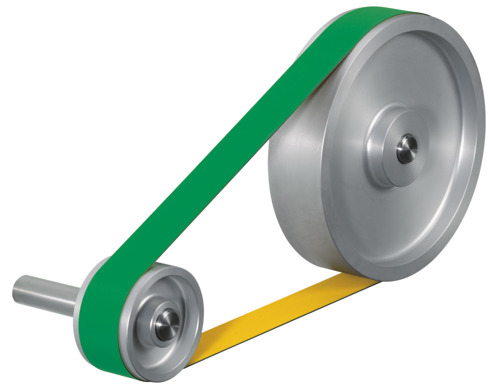

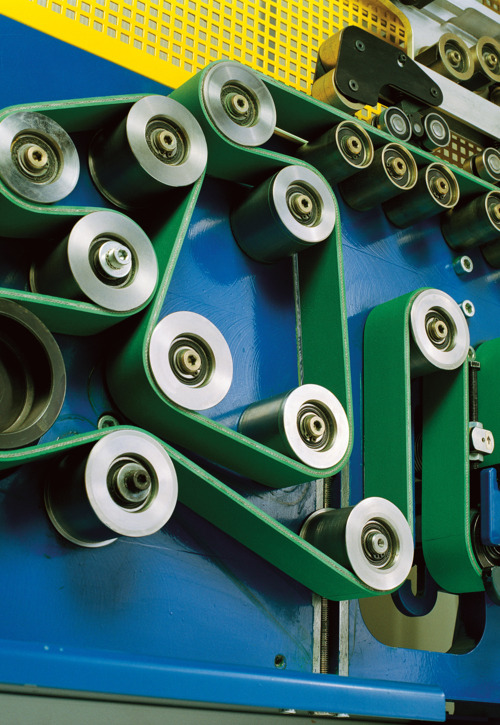

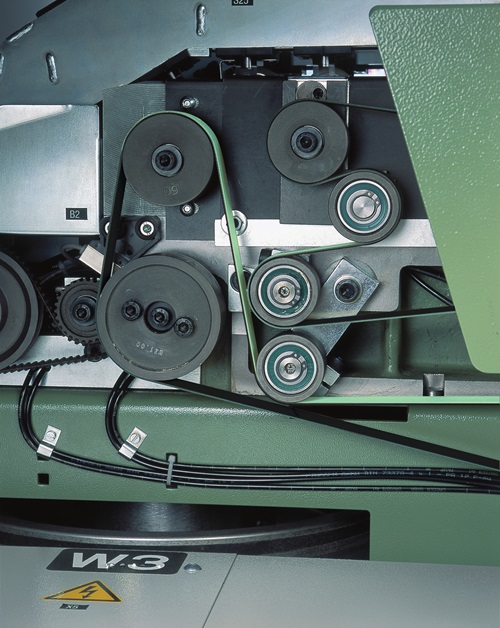

We offer an extensive range of power transmission yarn processing belts, spindle tapes, and conveyor belts to meet the most demanding requirements of yarn manufacturing, and letting you select the best solution to meet your particular application needs.

We have theright answerfor your challenges

" data-content="

The conveyor belts handling the full bobbins require a long lasting conveying side surface, which is typical of the Habasit conveyors for textile industry.

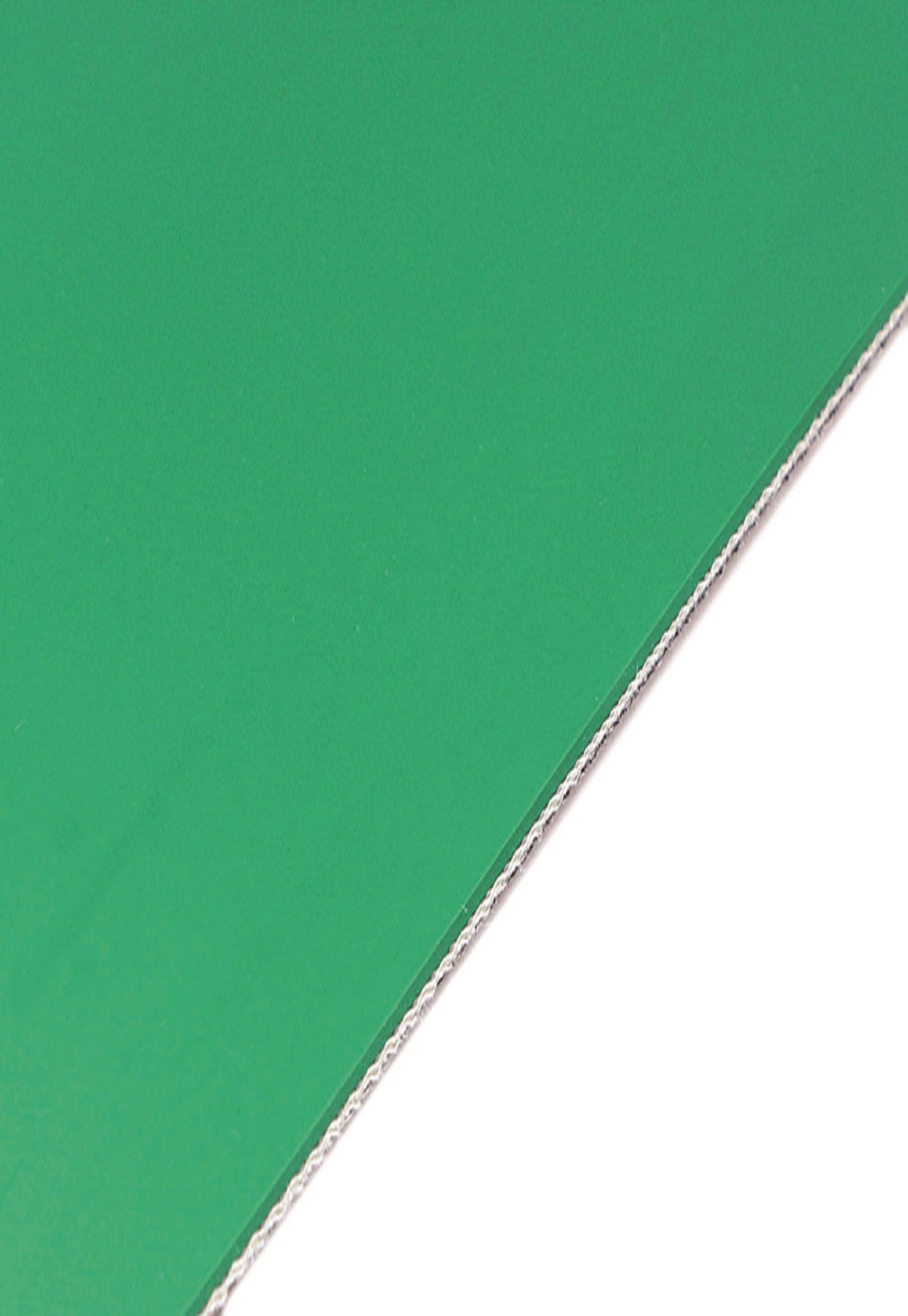

To meet the needs of a long belt life through abrasion resistance, Habasit provides high performance rubber covers of power transmission belts.

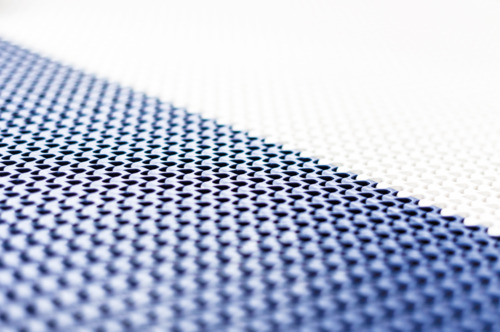

In case of spindle tapes both the fabric surface of the whirl side and the rubber, or thermoplastic polyurethane, cover of the driving pulley side guarantee a very good abrasion resistance.

" data-tags="Abrasion resistance" data-email="">" data-content="Good dimensional stability maintains the uniform spindle rpm required for high-quality yarn, while ensuring a long belt service life. Habasit supports your productivity through belts that do not require retensioning and are not subject to elongation.

" data-tags="" data-email="">

" data-tags="" data-email="">

" data-tags="" data-email="">

" data-tags="" data-email="">

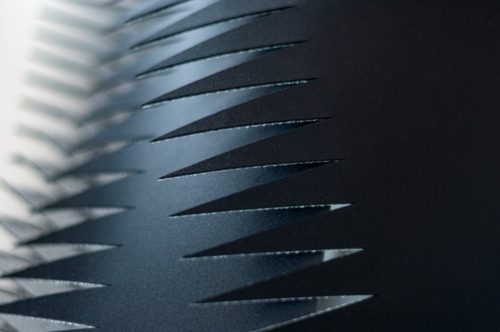

Due to the very critical working operations, the power transmission belts have to be professionally joined.

If the environment is rather hot and humid the strength of the joining area can be maximized by selecting polyamide belts that need the Thermofix joining method.

" data-tags="" data-email="">