Highly durable and dimensionally accurateopen-end timing belts

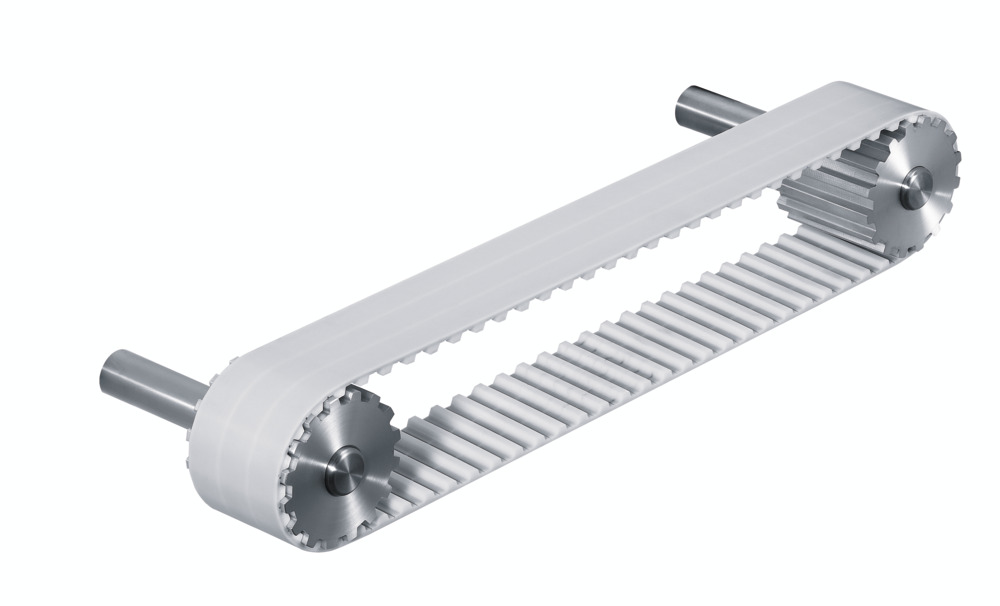

Featuring exact tooth pitches and very small tolerances, HabaSYNC open-end timing belts guarantee parallel and linear synchronicity for a wide range of different conveyor applications. The belts provide precise positioning and gentle product conveyance, while supporting improved efficiency due to tighter product spacing on the belt.

Open-end timing belts can be joined endless to any length, either in the workshop or directly on the conveyor. If required, friction-reducing, wear resistant polyamide fabric can be added on the tooth side, and abrasion resistant polyamide fabric on the conveying side.

Characteristicsof the open-end timing belts

Our HabaSYNC open-end timing belts offer the following features:

Mechanical properties

Mechanical properties

- Friction / adhesion

- 释放

- Abrasion resistance

- Wear resistance

- Cut resistance

- Compressibility

Physical properties

- Antistatic

- Electrical conductivity

- Cold resistance

- Hydrolysis resistance

- Flame retardant

Chemical properties

- Oil and fat resistance

- Acid and base resistance

- Ozone and UV resistance

- Food approved

- Easy to clean

Explore our range for open-end timing belts

" data-content="

" data-tags="" data-email="">

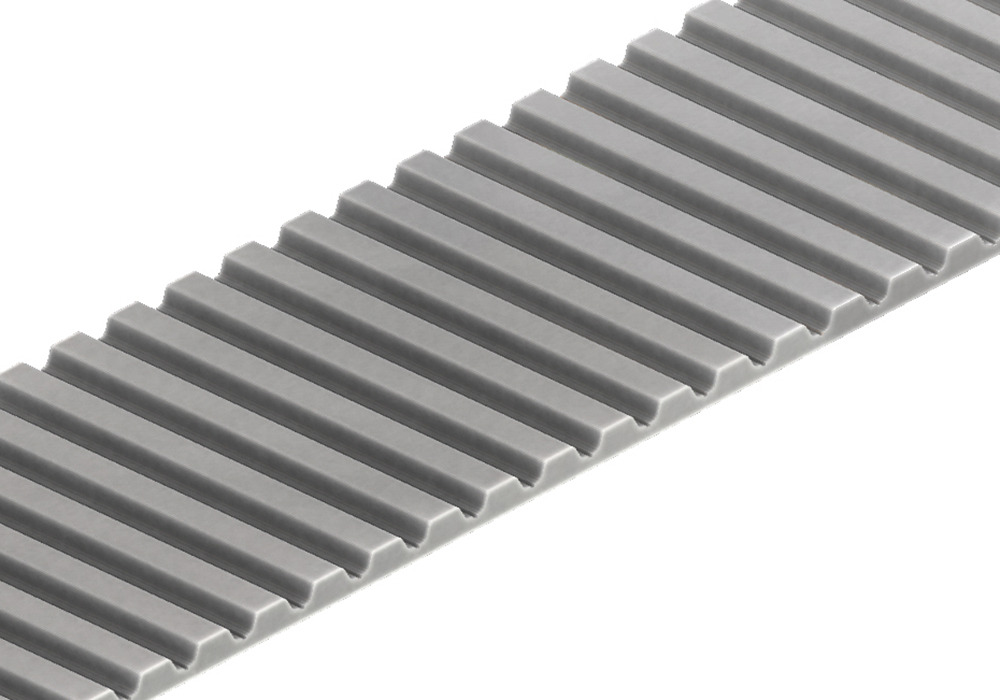

" data-content="- Standard trapezoidal tooth shape

- Available pitches: T5, T10 and T20

- Original metric tooth design (DIN 7721)

Optimal for conveying applications- Balanced tension member design for reliable tracking performance

- Wide range of polyurethane and tension member options

" data-tags="" data-email="">

T-Series

- Heavy duty trapezoidal tooth shape

- Available pitches: AT5, AT10 and AT20

- Original metric tooth design (ISO 17396)

- Superior backlash control

- Sturdy tension member design for reliable tracking performance

- Wide range of polyurethane and tension member options

" data-tags="" data-email="">

AT-Series

- Curvilinear tooth shape

- Available pitches: 5M, 8M and 14M

- Original metric tooth design (ISO 13050)

- Increased tooth depth for high torque transmission and precise positioning

- Low noise and vibration level

" data-tags="" data-email="">

HTD-Series

- Trapezoid tooth shape

- Available range of pitches: XL, L, H, XH

- Optimal for conveying applications

- Original metric tooth design (ISO 5296)

- Balanced tension member design for reliable tracking performance

- Wide range of polyurethane and tension member options

" data-tags="" data-email="">

Imperial-Series

" data-content="

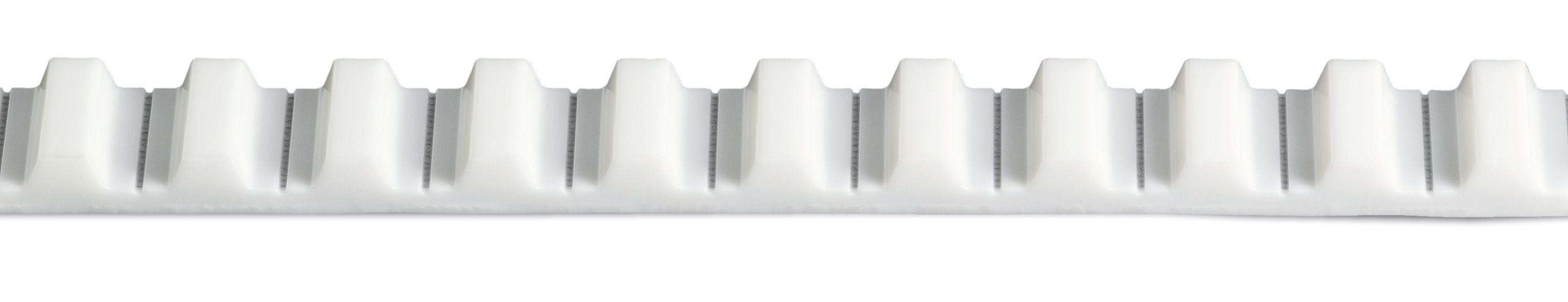

- Self-tracking timing belts provide improved tracking properties for side loaded applications

- Notched guides on AT10 and H pitches

- Notched or unnotched, welded V-guides available for all timing belt types

- No need for pulley flanges

- Solid or notched guides in any offered size can be added to all Habasit timing belts by welding to provide you best in class solutions adjusted to your needs

- Balanced tension member design for reliable tracking performance

- Wide range of polyurethane and tension member options

Self-Tracking Types

" data-content="

- Double-sided timing belts are used to transfer power on both sides instead of conveying products

- Available pitches: DT5, DAT5, DT10, DAT10, DT20, DAT20, D5M, D8M, D14M

- Manufactured according to ISO 17396 (tooth over tooth gap) for trapezoidal shapes

- Manufactured according to ISO 13050 (tooth over tooth) for curvilinear tooth shapes

- Balanced tension member design for reliable tracking performance

- Wide range of polyurethane and tension member options

" data-tags="" data-email="">

Double-Sided Types

- Flat belts are great alternative to standard flat belts where dimensional stability and strength properties are key features

- Different thickness variants offer best in class strength properties and high reliability and performance

- Balanced tension member design for reliable tracking performance

- Wide range of polyurethane and tension member options

- Fully customizable options

" data-tags="" data-email="">

Flat Belt Series

- Trapezoidal tooth shape with fully encapsulated cords and belt edge protection

- Available in T10 and T5 pitches

- Original metric tooth design (ISO 17396)

- Best in class food grade polyurethane combined with aramid tension member

- Designed for food safety by food experts (EU, FDA and USDA meat and poultry food conformity)

Closed Flight Series