Tailored solutions fornonwovens

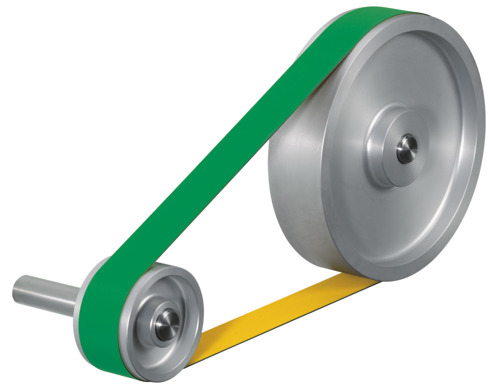

High-quality materials coupled with our state-of-the-art manufacturing process and years of experience ensure innovative and customized solutions for your nonwoven belting needs.

As your partner in all belting requirements, we are here to support you with every challenge. Whether you are looking for minimum downtime, professional belt installation, or other specific needs, we can help you achieve the highest possible performance for your operations.

We have theright answerfor your challenges

Select

" data-content="Aggressive chemicals can damage the belt, causing cracking of the belt surface and a reduction in belt service life. Habasit uses chemical-resistant materials that are non-brittle and avoid micro cracking of the belt surface, ensuring a long service life.

" data-tags="" data-email="">

" data-content="Our belts have electrically conductive properties that prevent fibers from sticking to the belt due to static charges. This eliminates fiber accumulation and thus helps to reduce unscheduled downtime." data-tags="" data-email="">

Chemical resistance

" data-tags="" data-email="">

Anti-static properties

Because belts used for nonwovens are prone to scratching and high wear, Habasit produces belts and covers with scratch- and wear resistance, as well as a low and constant coefficient of friction. This also supports longer belt service life.

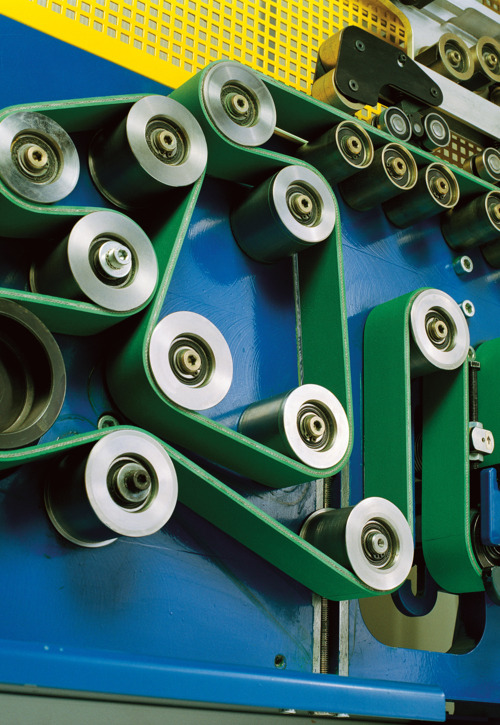

Our crosslapper belts are an ideal combination of high transversal rigidity, extremely light weight, and excellent mechanical properties, including lateral stiffness, good tracking, and scratch- and wear resistance.

" data-tags="" data-email="">

Wear resistance

" data-tags="" data-email="">

Precise positioning

" data-tags="" data-email="">

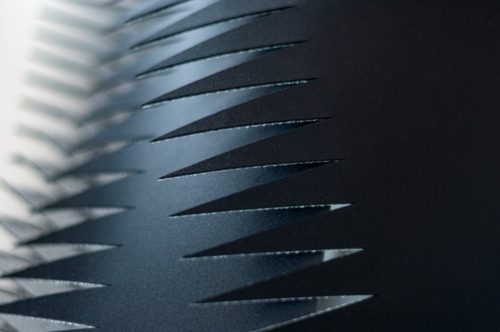

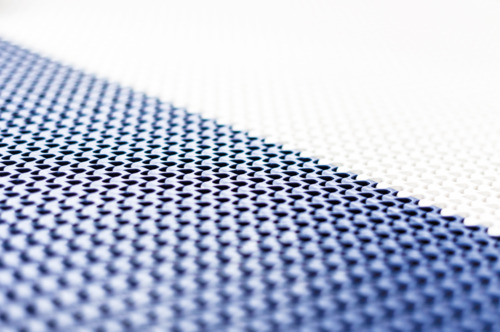

Specific surface structures