Delivering what you need forprimary packaging

We understand the importance of meeting all statutory and market requirements, particularly when handling delicate materials like foods, chemicals, pharmaceuticals, and dangerous goods.

Habasit offers an extensive variety of options to meet

Habasit offers an extensive variety of options to meet

your packaging application requirements. At the same time, you can expect easy belt installation, maintenance with minimum downtime, precise positioning, and belts that remain reliable no matter what operating temperatures your applications run at.

We have theright answerfor your challenges

Select

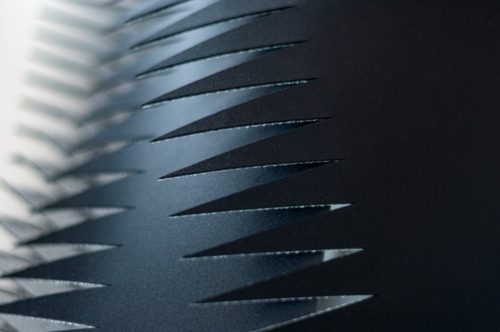

Ensuring reliable small transfers that maintain product positioning is critical. Depending on the size of the product, the capacity for tight transfers can be the key factor in belt selection. Whether roller, fixed nosebar, or knife edge transfer, Habasit can provide exactly the right solution, for 3 mm nosebar radius or less.

" data-tags="" data-email="">

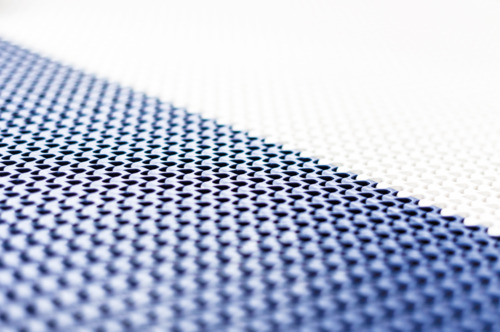

" data-content="Precise positioning and transfer of goods is essential, and depends on a flat and uniform belt surface. Habasit belts offer high friction sufaces to prevent product slippage. Our belts are also designed to eliminate belt elongation, which can also cause positioning issues." data-tags="" data-email="">

Small transfers possible

" data-tags="" data-email="">

Precise positioning

" data-tags="Abrasion resistance" data-email="">

Abrasion resistance

" data-tags="" data-email="">

Efficient cleaning and sanitation

" data-tags="" data-email="">

Excellent belt tracking

Featured products

Other products