Outstanding qualityfrom start to finish

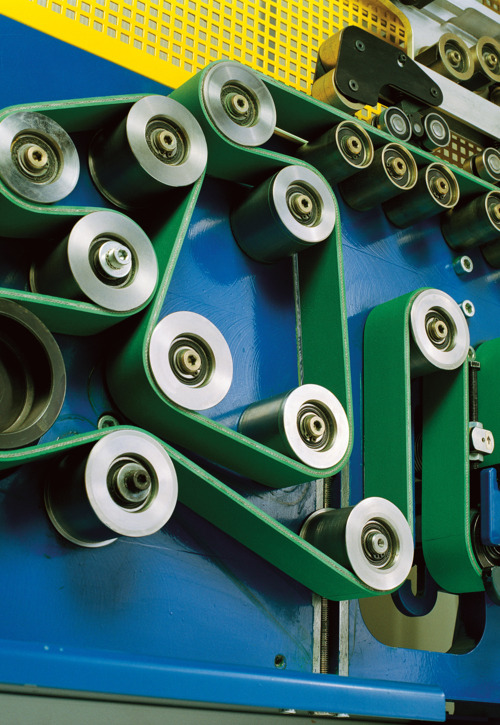

From the Banbury mixer to the shipping line, Habasit is your expertsolution partnerfor every application in the tire manufacturing process. Our application engineering and consulting expertise is with you from the start, complemented by our on-site fitting and total qualityafter-sales servicesperformed by highly qualified technicians.

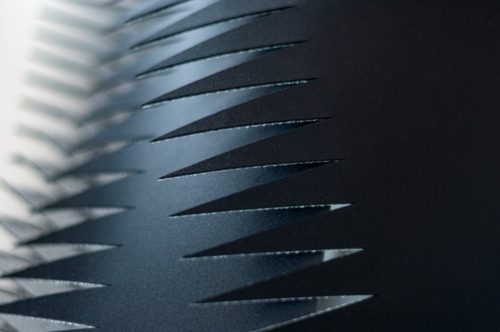

While we can support you at every stage, our solution for the tire building machine, the pulsing heart of every tire producing process, is worth particular emphasis. The patentedHabasithinge joint for timing belts comes into its own here, significantly reducing downtime for maintenance and ensuring that your machine delivers the highest productivity.

We have theright answerfor your challenges

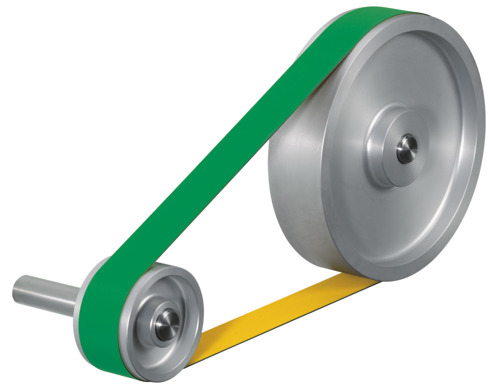

Featured products

Other products

What'snew?

Downloads