Robust solutionsfor the tire industry

Heat resistantmaterials

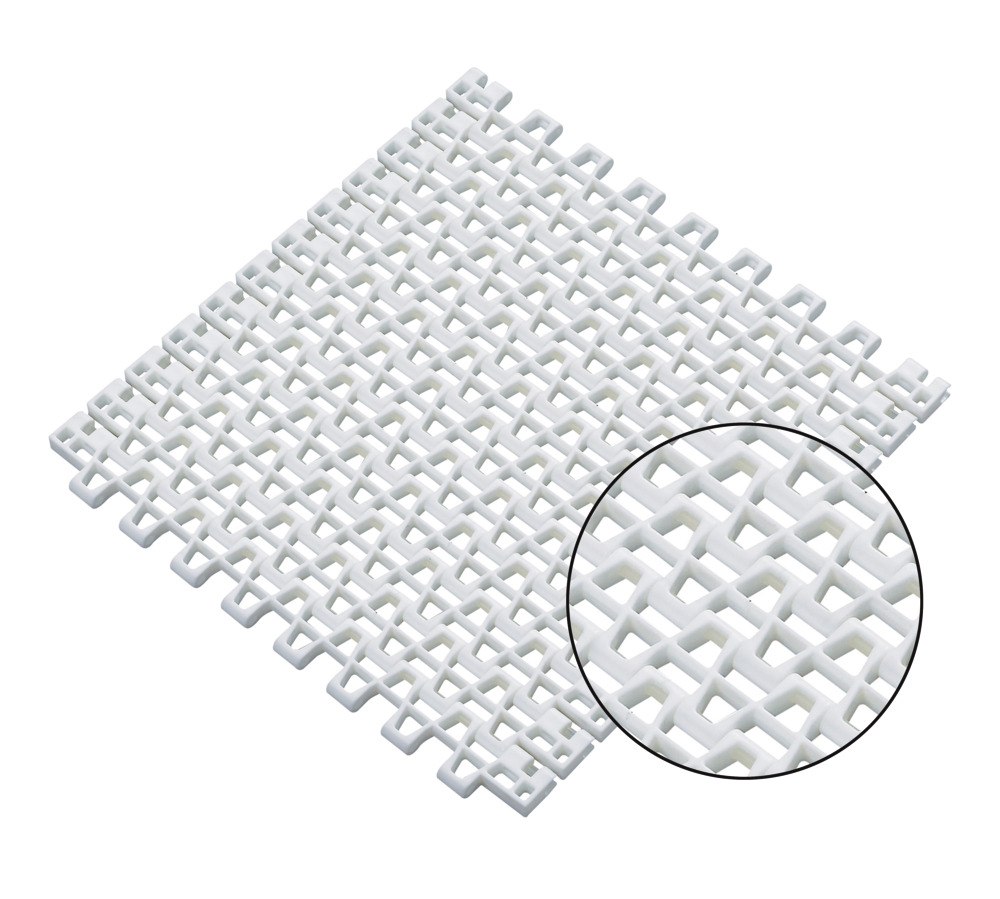

Many steps in the tire production process take place at elevated temperatures, which can be challenging to belts operating in such conditions.

The HabasitLINK product range includes materials that can cope with temperatures up to 240°C / 464°F - the hottest part of tire processing.

The high robustness of Habasit plastic modular belts prevents the hot rubber from sticking to the belt and avoids undesired contamination of the rubber band.

Cooling lineheroes

HabasitLINK plastic modular belts are well equipped to deal with the temperaturesand humidityfound onthe cooling line, and offera wide range of open surfaces to match yourprecisecooling target. The different belt types provide an open contact arearangingfrom 16%to 88%,tomatch theexactrequirements of the line.

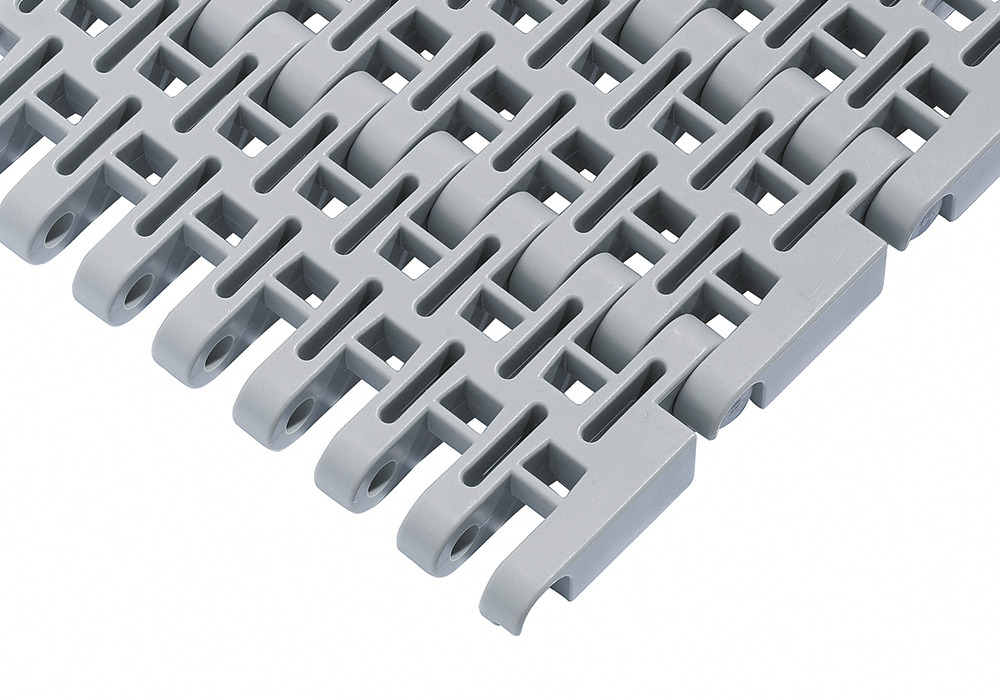

Molded forheavy-dutyapplications

In many tire industry applications, -such as the dip tank, the abrasion- and chemical resistance of the belt are key success factors.

HabasitLINK他avy-duty belts are the right choice for these demanding conditions. Their robust design and closed hinges deliver a long belt lifetime while minimizing unexpected downtime and production jams.

Tire deliveryacross the entire process

After curing, tires need to be handled, inspected, and stored. Initially, they are quite hot and their high grip hinders lateral transfers and diverting applications.

HabasitLINK solutionsfacilitatethe movement of tires onto the line,whileeliminating tire abrasion and jams.The belts’ robust roller retention system and high density ensure maximum reliability and long lifetimes. More specialized, customizedsolutions can helpwithtire handling,involvingroller angle positioning, for example.

HabasitLINK beltsare also used tomove the finished tires to the warehouse. The solution portfolio includes beltsthatcan handle tires on heavily inclined conveyors without slippage,thuspreventing production jams.