最小化停机时间框转换

我们有正确答案为您的挑战

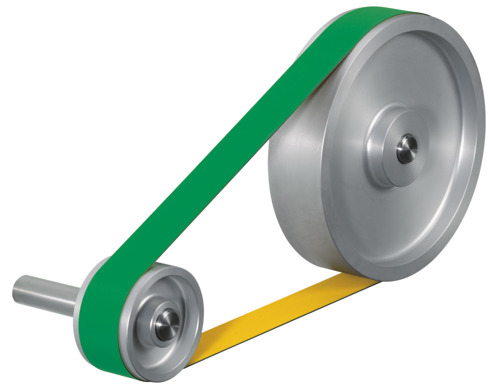

Machine downtime and maintenance, especially if unscheduled, hinders production and other critical functions, and can escalate into a headache for maintenance-, production-, and even operations managers.

Habasit’s top-quality belting prevents unplanned downtime and ensures high productivity throughout its lifetime. Good abrasion resistance and dimensional stability support long belt lifetimes and optimal performance. The combination of good flex-fatigue properties and robust materials also contributes to minimized downtime.

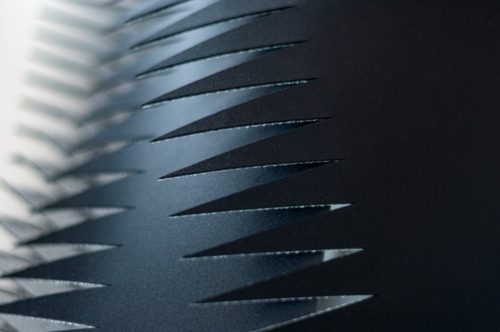

" data-tags="Reduced machine downtime and maintenance" data-email="">High wear and abrasion on board converting lines is a challenge met by using robust and durable materials for our belts.

Good abrasion resistance and dimensional stability support optimal performance and minimal machine downtime. These features, together with excellent flex-fatigue properties, allow best-in-class lifetimes for our belts.

" data-tags="Abrasion resistance" data-email="">Habasit solutions ensure the right surface properties for every conveyed board type.

Our belts offer a safe, smooth and consistent grip over the entire belt lifetime, delivering precise and reliable processing and transport of board without marking, scratching, or smearing.

" data-tags="No marking of the corrugated board" data-email="">" data-tags="No slippage" data-email="">

" data-tags="Excellent belt tracking" data-email="">

" data-tags="Abrasion and wear resistance" data-email="">

" data-tags="Precise folding of the board" data-email="">

" data-tags="Anti-static properties" data-email="">

Since paper dust is generated during the manufacture of boxes and corrugated board, the environment is very dusty. Belts that are exposed to heavy dust have a potential risk of belt abrasion.

Our belts are highly abrasion resistant and provide a best-in-class lifetime in these challenging operational conditions.

" data-tags="Resistance to heavy dust" data-email="">